Laser Cut, Laser Cutting, Lasers Cut

Laser Cut, Laser Cutting, Lasers Cut

Exploring Laser Precision: The Differences Between “Laser Cut,” “Laser Cutting,” and “Lasers Cut”

In today’s world, laser technology has transformed how we cut, shape, and design materials. But if you’re just getting started with laser services or simply curious, you may wonder about terms like “laser cut,” “laser cutting,” and “lasers cut.” These phrases often appear interchangeable but have unique uses. In this article, we’ll dive into what each term really means and how understanding these can help in selecting the right laser services for your project.

What is Laser Cutting?

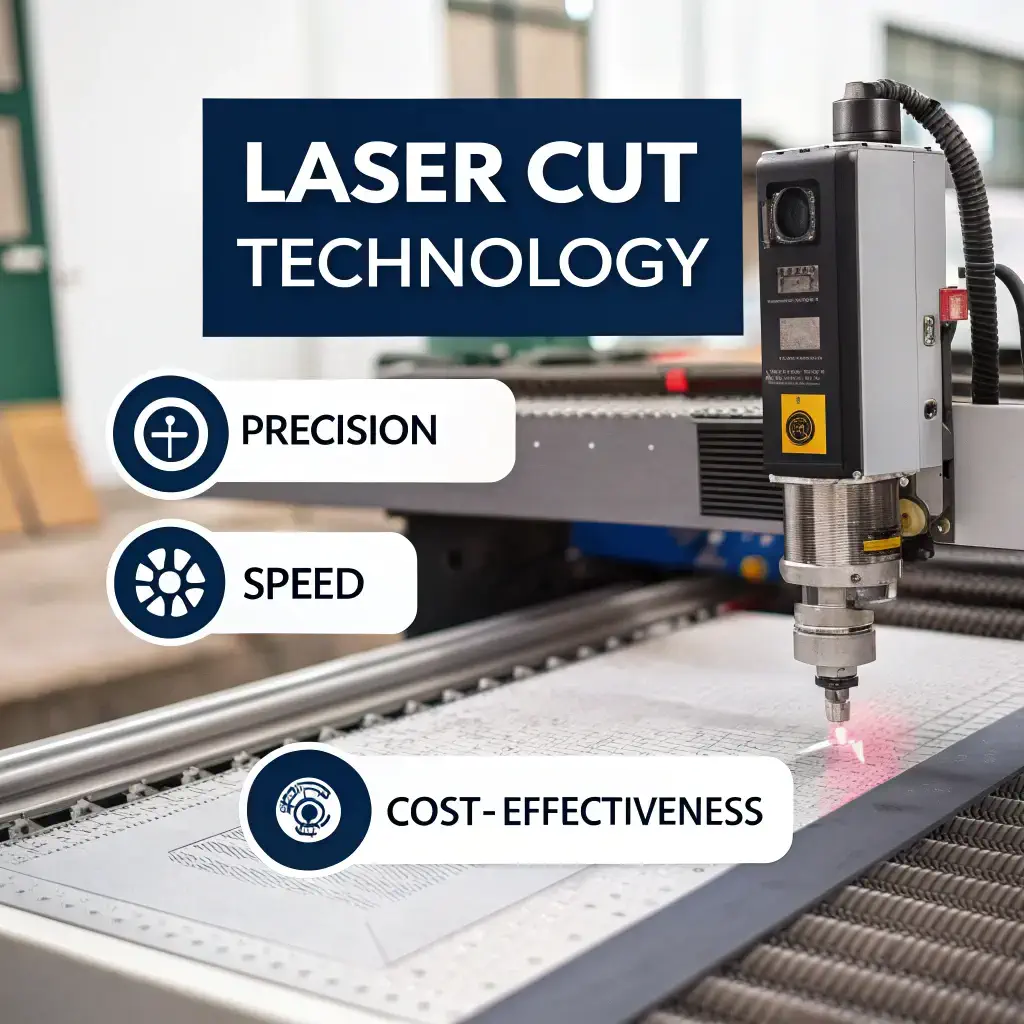

Laser cutting is a fabrication method that uses a focused laser beam to cut materials. It is widely used in various industries, from aerospace to jewelry, because of its precision and speed. Unlike traditional methods, laser cutting creates highly accurate and smooth cuts, reducing the need for secondary finishing.

Key Benefits of Laser Cutting:

- Precision: Cuts are highly accurate, often within millimeter tolerances.

- Efficiency: Fast cutting speeds mean reduced lead times.

- Versatility: It works on metals, plastics, wood, acrylic, fabric and more.

Laser-cutting is commonly discussed in the manufacturing and design industries. When people refer to laser-cutting, they typically mean the process or technology itself rather than a specific product.

Understanding “Laser-Cut”

The term “laser-cut” is frequently used to describe items that have been shaped or manufactured using laser technology. In this context, “laser-cut” is often used as an adjective, referring to the final product. For example, you may hear people mention “laser-cut metal parts” or “laser-cut designs.”

Common Uses of “Laser-Cut” in Industries:

- Jewelry: Delicate, intricate patterns are popular in laser-cut jewelry.

- Furniture: Laser-cut wood and metal are used for custom furniture designs.

- Architecture: Laser-cut models and designs allow for precise architectural detailing.

When a product is labeled “laser-cut,” it indicates it was made with precision and detail, highlighting the advantages of laser technology.

The Role of “Lasers-Cut”

“Lasers cut” is a phrase primarily used to describe the action that lasers perform. Unlike “laser-cut” and “laser-cutting,” which refer to the end product and the process, “lasers-cut” describes what lasers are actively doing. This phrase is more common in technical explanations where laser functionality is being discussed.

Examples in Context:

- “Lasers-cut intricate shapes into metal sheets.”

- “Industrial lasers-cut quickly through various materials, from plastics to wood.”

“Lasers-cut” is ideal for technical articles or descriptions focused on explaining laser functionality and applications.

Comparison Table: “Laser Cut” vs. “Laser Cutting” vs. “Lasers Cut”

| Term | Meaning | Typical Use |

|---|---|---|

| Laser Cut | Finished product created by laser | Describing items, e.g., “laser-cut metal” |

| Laser Cutting | Process of using laser technology to cut | General technology or process explanation |

| Lasers Cut | Action of lasers actively cutting | Technical explanations of laser capabilities |

Industries Benefiting from Laser Cutting

Laser technology is revolutionizing numerous fields. Below are some industries where laser-cutting terms are most commonly used:

- Manufacturing: Precision-cut parts for machinery and vehicles.

- Fashion and Design: Unique patterns and shapes for clothing and accessories.

- Electronics: Circuit board production and delicate component shaping.

Each term | laser-cut, laser-cutting, lasers -cut | finds its place in these fields, reflecting the many roles lasers play.

Choosing Between “Laser-Cut,” “Laser-Cutting,” and “Lasers-Cut”

For those seeking laser services, understanding and using these terms effectively can enhance.

- Laser-Cut

- Commonly used in e-commerce and product descriptions.

- Ideal for attracting users interested in purchasing or viewing finished products.

- Laser-Cutting

- A high-ranking keyword for educational or service-based content.

- Great for attracting users interested in the technology or considering services for custom projects.

- Lasers-Cut

- Best suited for technical blogs and articles.

- Appeals to audiences interested in the specifics of laser technology.

Using these terms strategically can increase visibility and attract more targeted visitors to your website.

Real-World Examples of Laser-Cut Products

Laser-cut products are everywhere, from household items to luxury goods. Here are some popular examples:

- Decorative Signage: Laser-cut metal signs are popular for businesses and homes.

- Custom Jewelry: Designers often use laser-cutting for intricate metal and wood jewelry pieces.

- Architectural Models: Architects use laser-cut materials to create accurate, scaled-down models.

Choosing the Right Laser Service for Your Needs

Understanding these terms helps in selecting the right laser service. Here’s a quick guide:

- For Product Manufacturing: Look for providers specializing in laser-cut items.

- For Custom Projects: Consider a company that emphasizes laser-cutting technology and processes.

- For Industrial Applications: Seek specialists in technical laser functions where lasers-cut through various materials effectively.

How much does it cost to laser-cut?

The cost of laser cutting depends on factors like the type of material, thickness, complexity of the design, and the laser cutter used. Typical costs range between $0.10 and $2 per minute of cutting time.

Some companies may charge based on the material’s size or thickness, with prices starting around $5 to $10 for smaller, basic cuts and increasing for intricate designs or high-quality materials.

What is the meaning of laser-cut?

Laser cutting is a fabrication process that uses a focused laser beam to cut materials into custom shapes and designs.

The high-powered laser vaporizes, melts, or burns through the material, allowing for precise, detailed cuts that are often cleaner than those made by traditional cutting tools.

What do lasers cut?

Lasers can cut a variety of materials, including:

- Metals: steel, aluminum, brass, and more

- Plastics: acrylic, polycarbonate, and ABS

- Wood: plywood, MDF, hardwoods, and softwoods

- Fabric: polyester, cotton, felt

- Other materials: paper, leather, and some types of foam

What cannot be cut with a laser cutter?

Materials that are difficult or unsafe to cut with lasers include:

- PVC and Vinyl: These materials release harmful chlorine gas when cut.

- Polycarbonate and certain plastics: They may not cut well and can create hazardous fumes.

- Glass and ceramics: While lasers can etch or engrave glass, they cannot easily cut through it.

- Thick metals: Standard laser cutters have difficulty with very thick metal; specialized lasers like fiber lasers are sometimes needed.

- Reflective materials: Reflective surfaces like mirrors or shiny metals can reflect the laser beam, potentially damaging the machine.

Laser-cutting is highly versatile but requires attention to material properties and safety considerations.

Laser technology is highly versatile, from industrial applications to creative projects. Whether you’re ordering a laser-cut product, researching laser-cutting technology, or learning how lasers-cut different materials, understanding these terms will help you make informed choices and communicate effectively in the world of laser services. Laser Products

Laser Cut, Laser Cutting, Lasers Cut

Laser Cut, Laser Cutting, Lasers Cut